ok, so today i went to reset the valve/rocker arm gap (is what i believe i'm looking for). anyway, it says to get the cam lined up just so that both valves are closed. i.e, the springs are not compressed at all. with the stock camshaft, there's a fairly high percentage of rotation in which niether the exhaust or intake valves are open(combustion, i would assume). anyway, i put my .254 mm feeler guage in the intake side of the cylindar farthest from the front, as that is the one i lined up first. it seemed that it could possibly be a little bit tighter, but nothing serious. i moved to the exhaust side and tried to put the feeler guage in, but it wouldn't fit. what gives? the cam lobes straddle an imaginary vertical line through the cam (they point downwards). of course, the imaginary line i speak of is not perfectly verticle, because the intake and exhaust sides are not level with one another. anyway, i can't figure out why i can get the feeler gauge in the intake side but not the exhaust. inline 6 cyl. 1989 325i. help!

valve adjustment...

- Thread starter e30fr3@k

- Start date

Woah, .254 mm??

First off, you only need the camshaft to be pointed DOWNWARD for the specific valve you are working on, not both exhaust and intake.

You should only be adjusting it to .25 mm COLD... and thats big.. you should adjust it to 0.20mm (.008 inches) when cold. I know bently says .25mm cold but .20 will make it a lot quieter.

Where exactly did you insert the feeler guage? It should be above the valve springs and below the rocker arm for the valve your adjusting.

When I first started to try to adjust my valves (just yesterday actually), the feeler guage made everything feel like it was to spec already -- which I knew it wasnt. So I decided to adjust every valve by loosening the setscrew nut (make sure you use a closed end wrench, if you use an open end you could slip off and damage the head and cause leaks) and then inserted my valve adjustement tool (i bought the spring loaded thing which is well worth the money!!! It allows you to put the feller guage between the valve and the eccentric and twist the spring loaded adjuster so it puts JUST the right pressure on the eccentric, so you can tighten the setscrew and get a perfect adjustment!!)

Also, dont try to turn the engine using the crank shaft dampener bolt like it says (and do NOT use the alternator bolt!! you'll probably damage the belt if you do it that way!!)

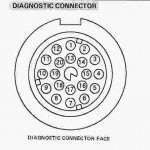

I was worried about doing this, but if you short out pins 11 and 14 in the diagnostics port, it will turn the engine over using the starter. I used a 4 guage peice of wire to short it out, just short it out very quickly. It works great and you dont have to remove spark plugs or try to reach the crank shaft.

First off, you only need the camshaft to be pointed DOWNWARD for the specific valve you are working on, not both exhaust and intake.

You should only be adjusting it to .25 mm COLD... and thats big.. you should adjust it to 0.20mm (.008 inches) when cold. I know bently says .25mm cold but .20 will make it a lot quieter.

Where exactly did you insert the feeler guage? It should be above the valve springs and below the rocker arm for the valve your adjusting.

When I first started to try to adjust my valves (just yesterday actually), the feeler guage made everything feel like it was to spec already -- which I knew it wasnt. So I decided to adjust every valve by loosening the setscrew nut (make sure you use a closed end wrench, if you use an open end you could slip off and damage the head and cause leaks) and then inserted my valve adjustement tool (i bought the spring loaded thing which is well worth the money!!! It allows you to put the feller guage between the valve and the eccentric and twist the spring loaded adjuster so it puts JUST the right pressure on the eccentric, so you can tighten the setscrew and get a perfect adjustment!!)

Also, dont try to turn the engine using the crank shaft dampener bolt like it says (and do NOT use the alternator bolt!! you'll probably damage the belt if you do it that way!!)

I was worried about doing this, but if you short out pins 11 and 14 in the diagnostics port, it will turn the engine over using the starter. I used a 4 guage peice of wire to short it out, just short it out very quickly. It works great and you dont have to remove spark plugs or try to reach the crank shaft.

This should help with the pins... i know the diagram is off a little bit of the actual port, but the numbers are 'engraved' into the diagnostics port so you can read them. I also re-read it and saw that you said "it seemed that it could possibly be a little bit tighter, but nothing serious."

Remember, you're talking about the difference of .05 mm.. thats SMALL, not enough for YOU to realize, but you'll hear a huge difference.

I adjusted mine to .009", which it runs super quiet when cold but when it gets warm i get a bit of a tap -- I'm readjusting it this weekend to .008". 1 more thing -- Make sure you replace that valve cover gasket!

Remember, you're talking about the difference of .05 mm.. thats SMALL, not enough for YOU to realize, but you'll hear a huge difference.

I adjusted mine to .009", which it runs super quiet when cold but when it gets warm i get a bit of a tap -- I'm readjusting it this weekend to .008". 1 more thing -- Make sure you replace that valve cover gasket!

Attachments

-

7.5 KB Views: 71

Last edited:

so you're saying i don't have to have both the intake and exhaust springs up at the same time? and i slid the guage in the only place it went through, which was right above the valve spring and right below the end of the arm(towards the outside of the unit). is .004 mm really that much of a difference? i suppose i'll just tighten it down a little more. i don't have any fancy tools, just a 3 mm hex wrench, a feeler and a set of sockets to do this job. also, when i started my car after giving up (due to rain, i swear![ROFL [rofl] [rofl]](/images/smilies/icon_smile_rofl.gif) ) the idle was SO erratic. from 1000 to 200 and then even stalling. i freaked out and took everything apart in my garage again; put it back together even more securely. seemed to fix the problem but then the oil light came on...wtf mate? anyhow, i added a good amount of oil (close to a quart), and the light went off. timing belt's being replaced tomorrow, so after that i'll see if i still need to readjust my valves.

) the idle was SO erratic. from 1000 to 200 and then even stalling. i freaked out and took everything apart in my garage again; put it back together even more securely. seemed to fix the problem but then the oil light came on...wtf mate? anyhow, i added a good amount of oil (close to a quart), and the light went off. timing belt's being replaced tomorrow, so after that i'll see if i still need to readjust my valves.

epj3 said:

inserted my valve adjustement tool (i bought the spring loaded thing which is well worth the money!!! It allows you to put the feller guage between the valve and the eccentric and twist the spring loaded adjuster so it puts JUST the right pressure on the eccentric, so you can tighten the setscrew and get a perfect adjustment!!)